Materials Mechanical Properties Simulator (MMS)

User ViewPoint

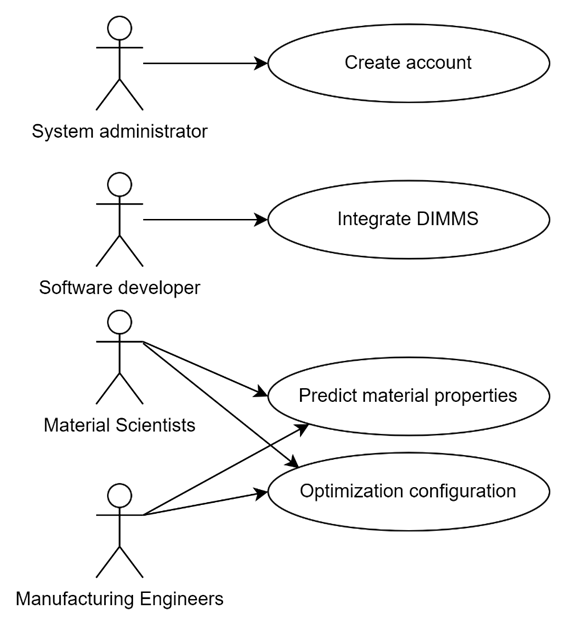

Usage Case Diagram Actors

General Description

The objective of the DiMAT MMS toolkit is to accurately predict materials mechanical properties. The input of the toolkit will be the material component fractions, compounds, microstructure parameters, as porosity or grain size. The toolkit generates outputs that include elastic properties, strength, and rheological properties of the material.

Model

Roles

Materials Scientist: This role entails utilizing the toolkit to predict material mechanical properties as a function of the composition, fractions, and microstructure parameters. The toolkit will be also used to define the optimization problem, formulating constraints and objective functions.

Manufacturing Engineer: The manufacturing engineer uses the DiMMS toolkit for optimization purposes. The toolkit can be used independently or integrated into more sophisticated software to suggest optimal material compositions or microstructures. Furthermore, the manufacturing engineer leverages the toolkit for more efficient decision-making.

Software developer: The software developer will integrate the DIMMS toolkit into a, optimization software, ensuring seamless integration and compatibility between the components.

System Administrator: The administrator will be responsible for supervising the operation of the toolkit and will define security policies, adding or removing eligible users.

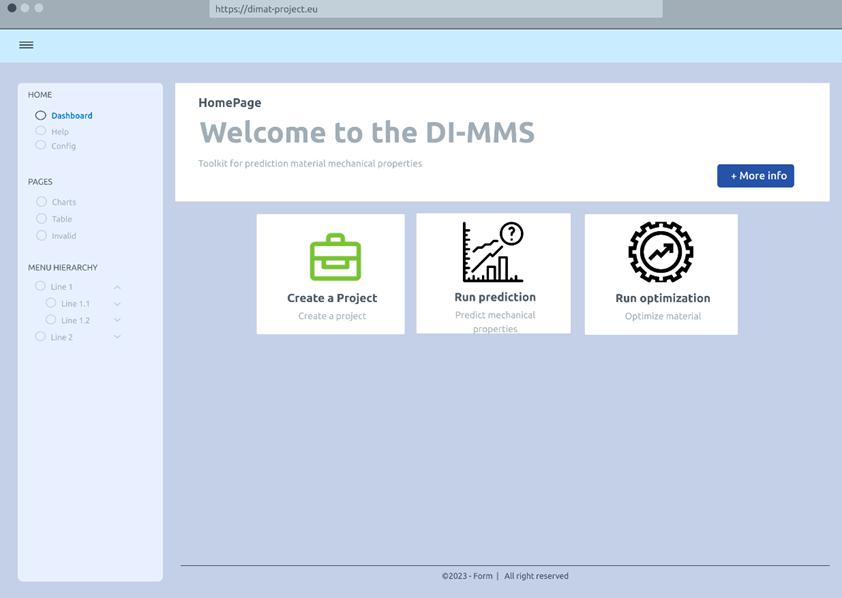

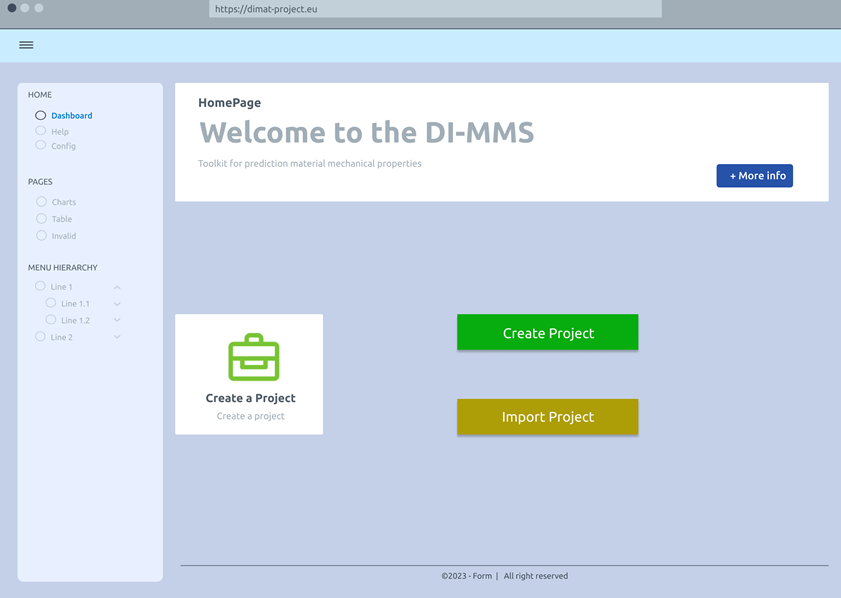

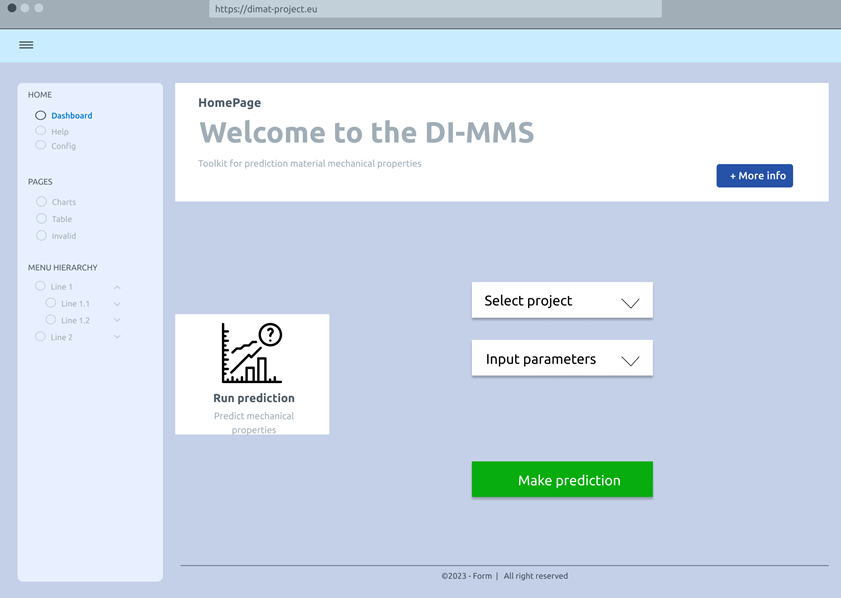

Mockups

Activity 1

View Home Page

Project Creation

Make prediction

Activity 2

Optimization

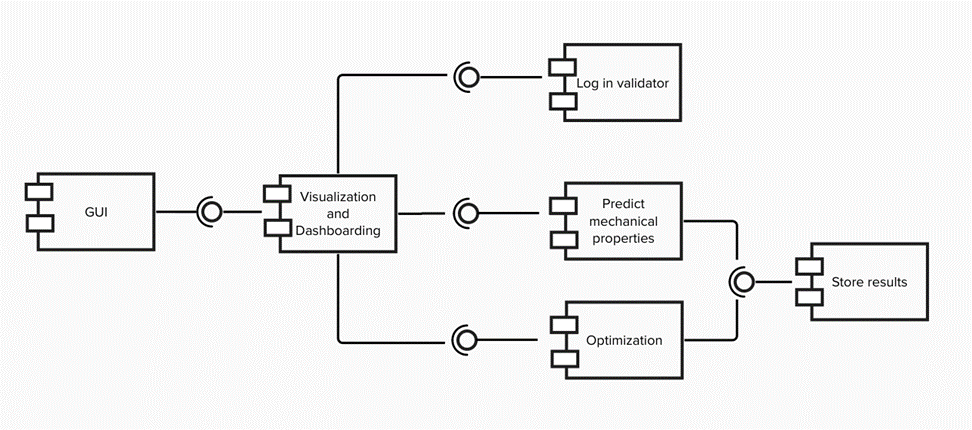

Functional ViewPoint

General architecture

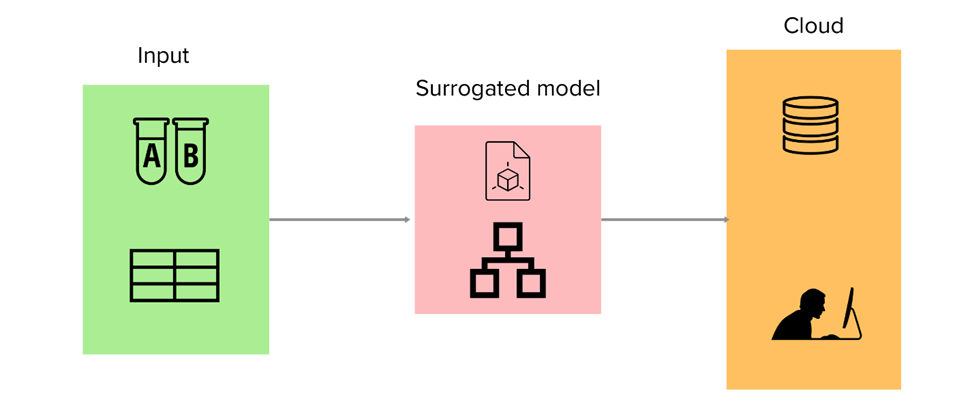

Implementation ViewPoint

Architecture of Toolkits

The surrogate model of the DMMS will link the input, compounds, fractions, micro-properties, microstructure with the output, the predicted mechanical properties. The surrogate model (SM) will be a simplified and computationally efficient representation of the physical models. The SM will capture the relationships between input variables and output responses of the original system and will operate in real time.

Required components

Hardware componentes

Various types of servers can be employed in the development of the mechanical models.

Database Servers: to handle data storage related to the DMMS toolkit and provide mechanisms for querying and efficient access.

Servers for simulations. DMMS toolkit will use dedicated servers for executing finite element and atomistic simulation models, implementing algorithms, and generating predictions of mechanical properties.

Data Storage

Simulation data: the input and output of simulation should be stored in specialized storage systems such as simulation data management platforms. Data for long-term storage should be better allocated into the Cloud and in collaboration with the DiMAT Cloud Materials Database.

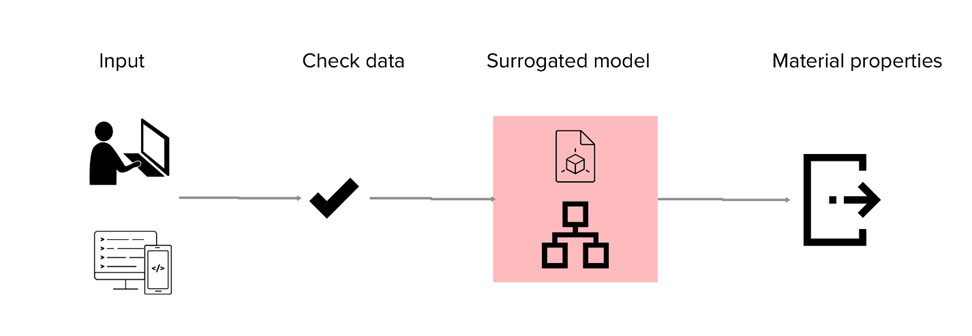

Implementation Map

The next figure provides a global overview of how the mechanical surrogate model is implemented. The starting point is the input from the user or an application that will provide the variables of the model. The data format and values of the variables will be checked, to avoid introducing an input out of the range for which the model has been trained. Then, the model map to the material property that will be the output of the process.