Materials Modeler (MM)

User ViewPoint

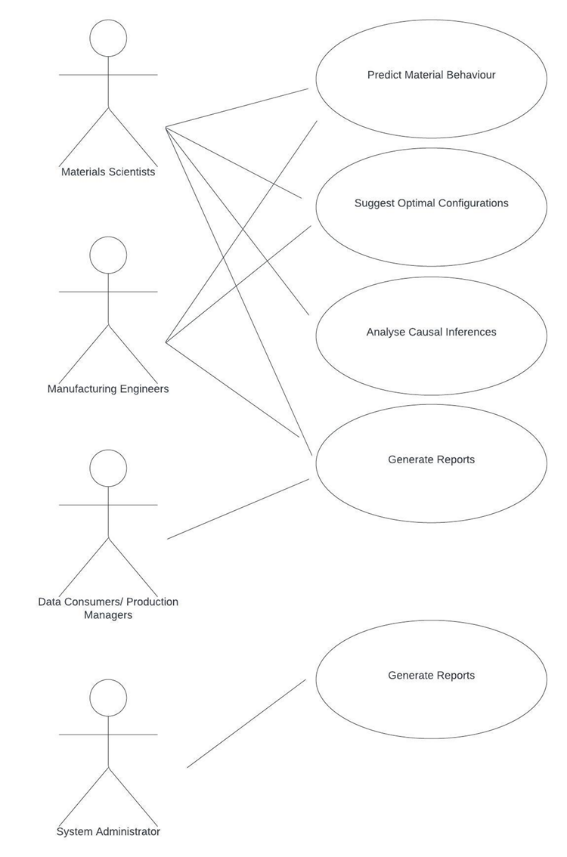

Usage Case Diagram Actors

General Description

The DiMAT Materials Modeler (MM) is a toolkit able to predict materials properties and behavior under different conditions during manufacturing processes, based on material structure, composition, etc., while inferring and suggesting optimal configurations. For instance, the DiMAT MM will be able to provide critical insights about which parameters/conditions affect the product quality during manufacturing on a microscopic scale. Moreover, the efficient material behavior prediction may provide control capabilities in microstructure mechanisms. For example, material damage or failure related behaviors can be predicted in time, and thus, permanent problems can be prevented via the application of the optimal configurations proposed by the DiMAT MM. The DiMAT MM solution will exploit robust AI (e.g., explainable AI, ML, DL), adopting causal inference approaches able to explain complex correlation patterns among interrelated phenomena, i.e., latent relationships between material structure and properties. The AI robustness will be ensured by testing the algorithms on different types of datasets, e.g., case study data, real industrial data, data collected from different industrial environments, etc. This solution will predict the material properties based on their structure and composition. Moreover, explainable AI will support converting the objective into understanding the underlying mechanisms and physical laws governing materials, leading to interpretable, trustworthy, and highly accurate estimations. All these actions aim to support increasing the production design rate, while decreasing the production cost.

Model

Roles

Materials Scientist: This role involves leveraging the toolkit for predicting material behavior based on various factors like material structure and composition. The materials scientist also uses the toolkit to analyze causal inferences and understand the complex relationships among interrelated phenomena.

Manufacturing Engineer: The manufacturing engineer uses the DiMAT MM toolkit to optimize manufacturing processes. This involves using the toolkit to predict material behavior and to apply suggested optimal configurations in the manufacturing processes. The manufacturing engineer can also use the toolkit’s report generation function for data-driven decision-making.

Production Manager/Data Consumer: The production manager/data consumer oversees the manufacturing process and makes critical decisions. This role also involves monitoring the toolkit’s data handling capabilities and ensuring it’s working efficiently with various datasets. They utilize the toolkit’s report generation capabilities to gain insights into material behaviors and manufacturing configurations, supporting their decision-making process.

System Administrator: The system administrator is responsible for managing the toolkit’s security measures. This includes defining security policies, as well as assigning roles and credentials to the different parties. They also ensure that the toolkit is well-maintained and up-to-date.

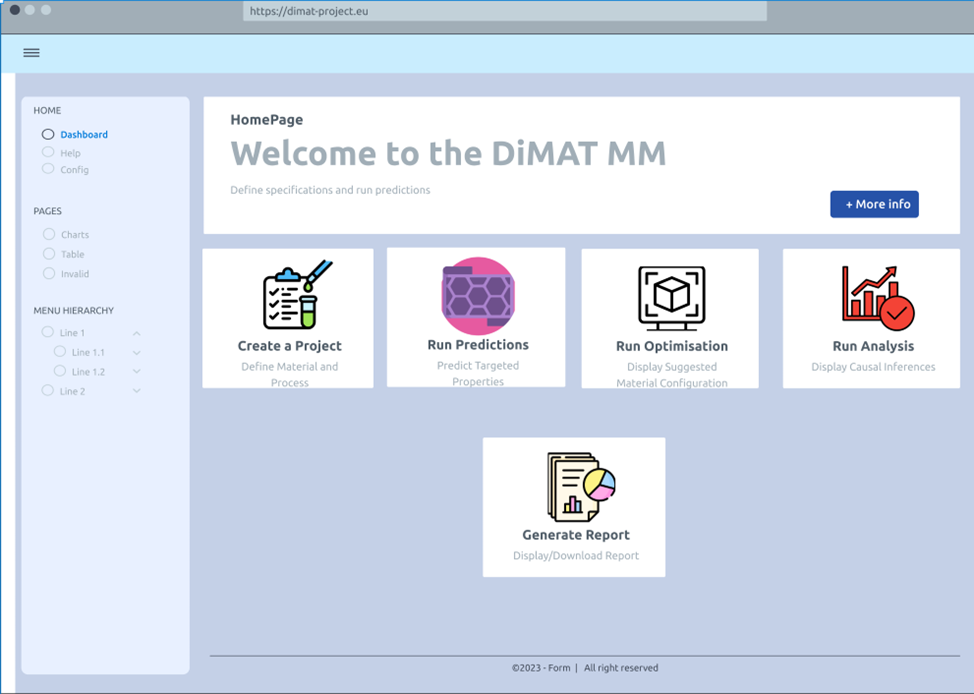

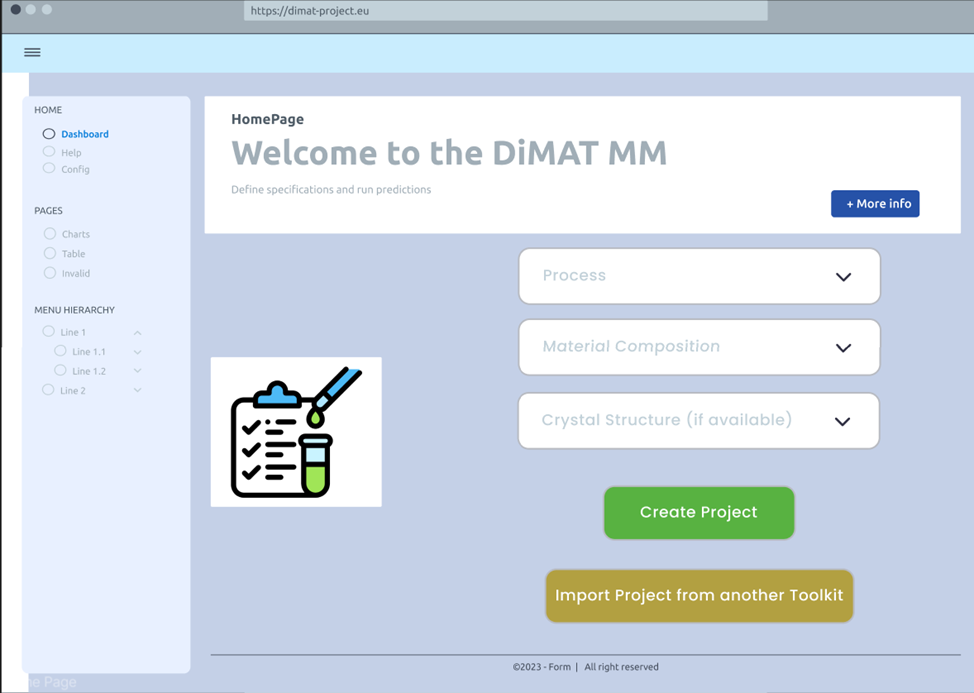

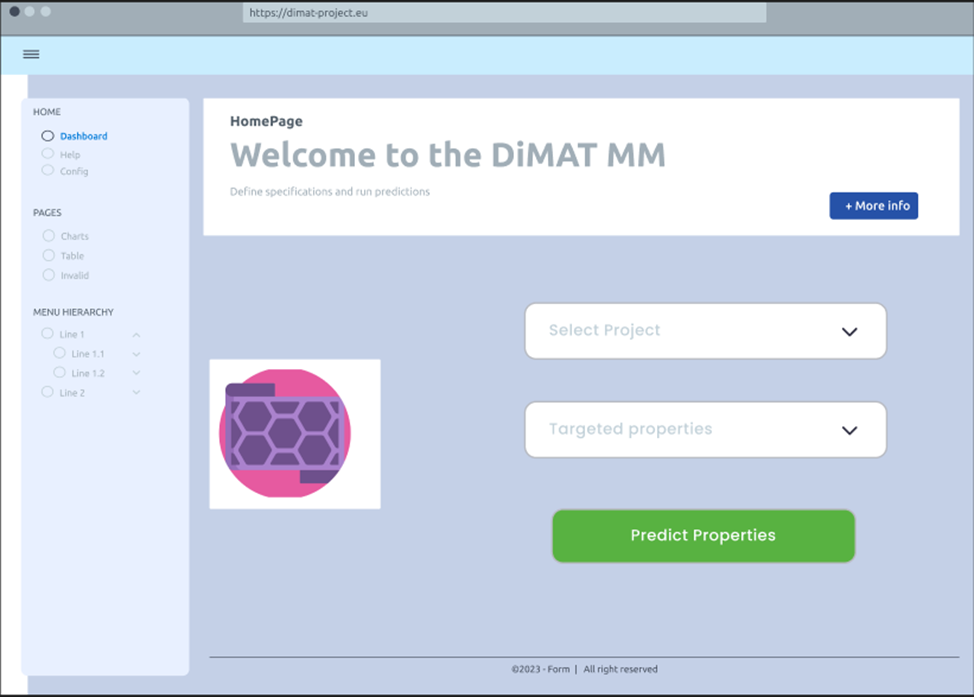

Mockups

Activity 1

View Home Page

Project Creation

Predict Properties

Activity 2

Suggest Optimal Configuration

Activity 3

Analyse Causal Inferences

Functional ViewPoint

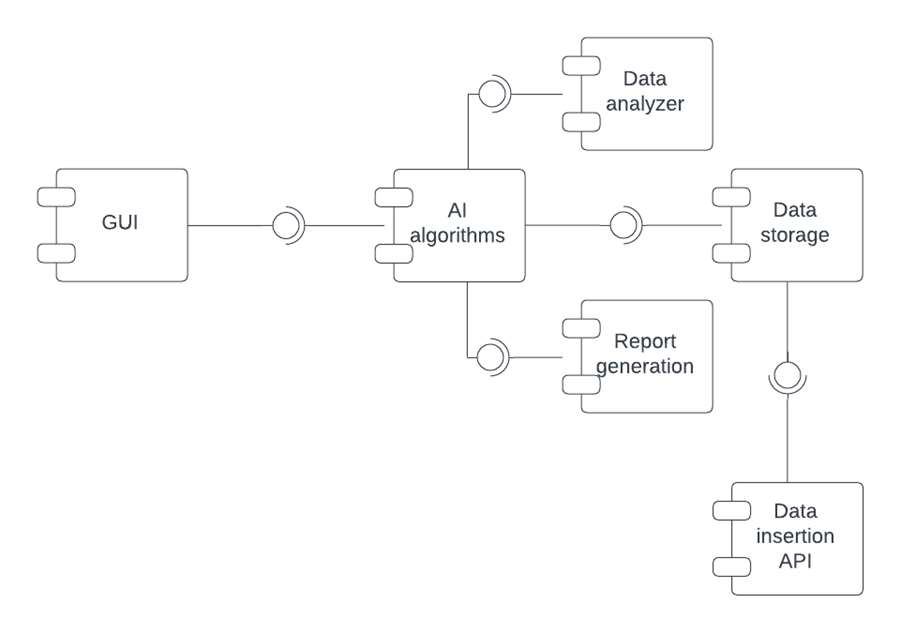

General architecture

Implementation ViewPoint

Architecture of Toolkits

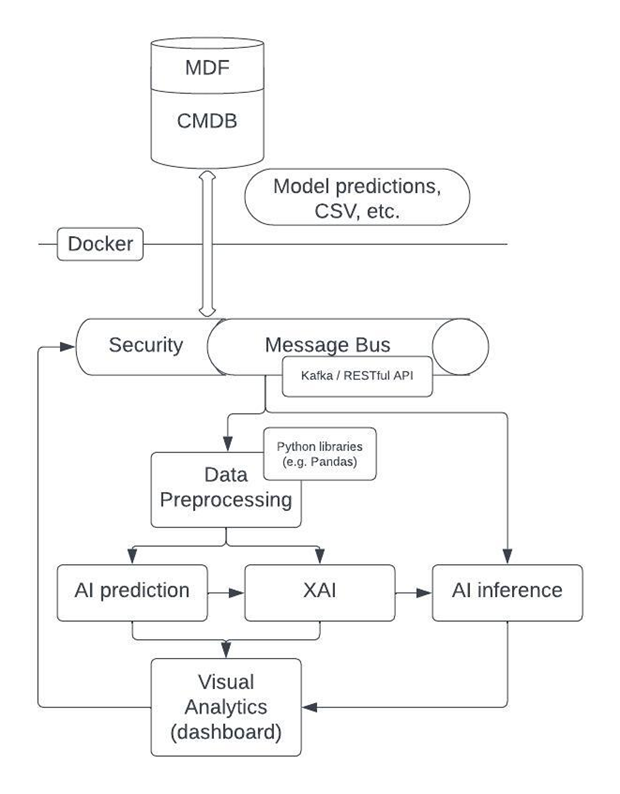

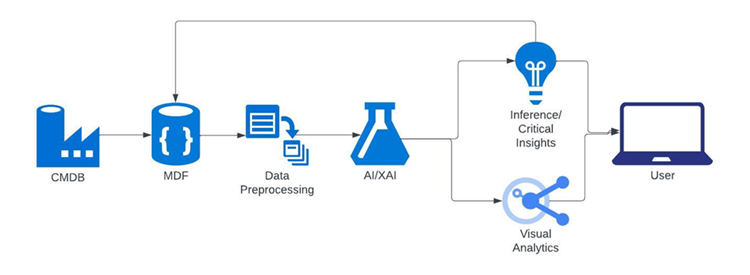

The above image depicts the Materials Modeler architecture. It is designed around robust AI and causal inference approaches, providing a system that can predict, infer, and suggest optimal configurations for various materials under diverse conditions. The core components include a communication layer, a data collection and preprocessing layer, an AI analysis layer, and a prediction and inference layer. The communication layer of the Materials Modeler (MM) interfaces using RESTful APIs, enabling seamless interaction with MDF and CMDB databases for efficient data retrieval. It also enables bi-directional information flow. Data is collected via the partners’ submissions which involve the material properties and behaviours under different manufacturing conditions. This data is then pre-processed and analysed using AI algorithms, including explainable AI, machine learning (ML), and deep learning (DL). The AI analysis layer uses these algorithms to infer latent relationships between material structure and properties and suggest optimal configurations. The prediction and inference layer then provides critical insights and potentially control capabilities in microstructure mechanisms.

Required components

Hardware componentes

For the effective implementation of the Materials Modeler (MM), the following hardware components are essential:

Server: High-performance server hardware, equipped with fast multi-core CPUs, is crucial for handling the complex computational load of AI/ML tasks. These servers will house the Docker containers that the MM operates within.

GPU: To optimize the performance of deep learning elements in the MM, the incorporation of powerful Graphics Processing Units (GPUs) is vital. Dockerized deep learning tasks can leverage these GPUs to significantly accelerate computational processes.

Temporary Storage (RAM): High-capacity, rapid-access Random Access Memory (RAM) is required to store intermediate data during computations and to ensure the efficient running of the MM software in its Docker environment.

All these components should be configured to support Docker-based deployment, promoting flexibility, scalability, and isolation of resources and processes.

Data Storage

Long-term storage, possibly cloud-based, is utilized for historical data and long-term pattern analysis. The Materials Database Framework, an ontology-based database constructed atop the Cloud Materials Database, will facilitate efficient data exchange between each toolkit, with a particular focus on the Materials Modeler.

Implementation Map

The implementation map, which also serves as the data flow diagram, starts with the data collection phase, where initial data is gathered. This data then proceeds to an in-depth preprocessing stage, setting the stage for more refined analysis. Next, it moves into the AI analysis layer, where it is enhanced by Explainable AI (XAI) algorithms. These algorithms are integral to the process, providing intelligible decision-making properties and contributing to the accuracy and interpretability of the outcomes. Following the analysis, the processed data is channelled to the prediction and inference layer. This is where the final model outputs and insights are produced. The results are subsequently relayed to a user-friendly interface for visualization. Here, the insights are displayed in a comprehensive and interactive manner, fostering a clear and thorough understanding of the results. The last stage in the implementation map reflects the closing loop in the data flow process. It shows the channelling of these insights back into the Materials Design Framework, ensuring they are available for future iterations and continuous improvement of the system.